Machine Condition Monitoring and Maintenance Optimization

The Cormind-SEPEX condition monitoring System which sets up your maintanence process in the minutes, is transfered it the real-time and efficient. Benefit from the machine’s data power to obtain the longer equipments’ running time and health.

CONNECT TO ALL MACHINES

Monitor and visualise the every machine and its parts instantly.

MONITOR AND ANALYZE MACHINE HEALTH:

Monitor and visualise the every machine and its parts instantly. Easily analyze based on visualized data.

TAKE ACTION AT THE RIGHT TIME

Keep machines running with optimized maintenance alerts with important KPIs, machine alarms and thresholds.

THE PROBLEM

IN MAINTENANCE

PROCESSES

Monitor the real-time machine’s conditions to prevent the unexpected, costly breakdowns and its durations for the interference at the right time.

Solution:

OPTIMIZED MAINTENANCE PROCESSES

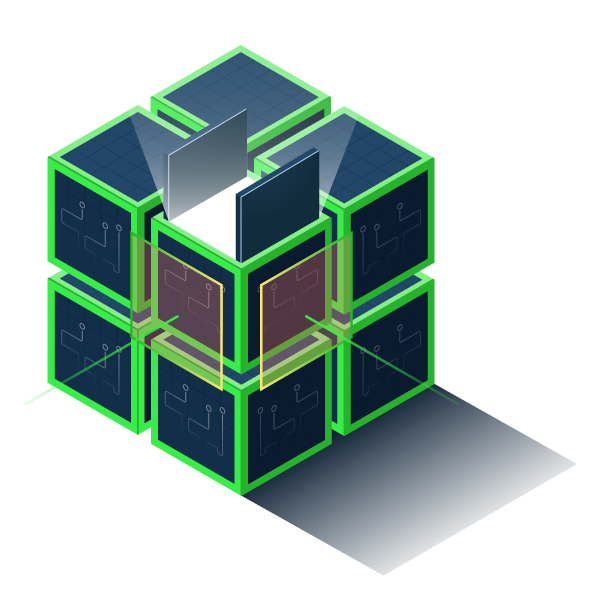

HOW IT WORKS?

1. COLLECTING PLC DATA

Collect, connect and contextualize the data automatically from the machines and operators.

2. CONNECT TO THE SENSOR QUICKLY AND EASILY

Attach the external sensors with digital and analog IO which can be remotely managed and configured through the web interface or attach the old equipments. .

3. USE THE DATA FASTLY

The ability of automatically captured data and use it, provides analyzed machine data and predictions.

Advanced Machine Analytics

Solve Problems with Real-Time Data

CONDITIONAL MONITORING

View and manage the conditions and health of your machine assets; and also view and export the real-time machine data and alarms as time series data and charts to determine and solve the problems.

REMOTE SERVICE

Share your machine’s data with service provider instantly to provide the remote service and get your machines online more faster.

ALARM AND WARNING METHOD

Warn to the right person at the right time when the action has to be taken. . Observe the situations with the reappointments, analysis, fully audit tracking and workflow.

ALARM ANALYSIS

Determine with the alarm summary which alarms cause the most stoppage in your workshop.

PREVENTIVE MAINTENANCE

Create workflows which manage the preventive maintenance from the machine boundaries in your CMMS based on calendar and uptime.

QUALITY CERTIFICATES

Are You Ready to Open Pandora’s Box for Your Business?